工件翻轉工裝+機械手機器人

設備(bei)名稱:沖壓自(zi)動翻(fan)(fan)轉臺,工(gong)件(jian)(jian)翻(fan)(fan)轉機(ji)構,產(chan)品翻(fan)(fan)面設備,工(gong)件(jian)(jian)翻(fan)(fan)轉工(gong)裝(zhuang),沖壓機(ji)械(xie)手翻(fan)(fan)轉臺等;

設備功能:實現(xian)工件(jian)的自動翻轉和定位;

設備參數(shu):產品(pin)吸盤或(huo)者夾具可以進行定制或(huo)者活動(dong),兼容(rong)尺(chi)寸(cun),使用伺服電機減速機傳(chuan)動(dong),工裝(zhuang)可實現工件(jian)180°翻轉(zhuan)或(huo)定制翻轉(zhuan)角(jiao)度;

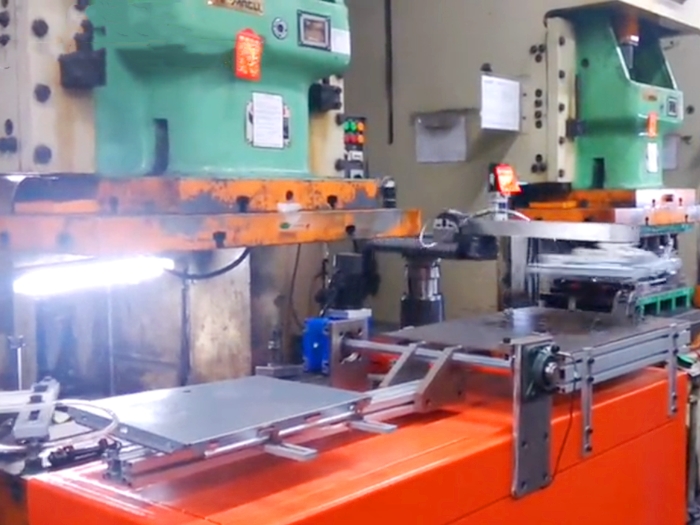

設備配套:翻轉(zhuan)臺往往在(zai)沖(chong)壓(ya)工序,拉伸工序,加工中心,機(ji)床加工工序中使用(yong)較多,常用(yong)于配套沖(chong)壓(ya)機(ji)械手(shou)關節式,擺臂式等機(ji)器(qi)人機(ji)械手(shou)使用(yong);

設計廠(chang)家:東莞市海智機器人自動化科技有限公司自主開發設計,海智可根據實際的工件情況,使用條件,機器人機械手情況進行專業的非標定制生產;

使用舉例:在(zai)五金沖(chong)壓(ya)工(gong)(gong)(gong)序(xu)中大部分工(gong)(gong)(gong)件(jian)從材料(liao)到成(cheng)(cheng)型都(dou)需要(yao)經過幾道(dao)(dao)工(gong)(gong)(gong)序(xu),而在(zai)多道(dao)(dao)沖(chong)壓(ya)工(gong)(gong)(gong)序(xu)中有要(yao)切換工(gong)(gong)(gong)件(jian)面后再(zai)進行(xing)沖(chong)壓(ya)的(de)工(gong)(gong)(gong)序(xu),在(zai)前道(dao)(dao)工(gong)(gong)(gong)序(xu)機械(xie)(xie)手(shou)沖(chong)壓(ya)完(wan)成(cheng)(cheng)后放入(ru)翻(fan)(fan)轉臺進行(xing)工(gong)(gong)(gong)件(jian)翻(fan)(fan)面,在(zai)翻(fan)(fan)面完(wan)成(cheng)(cheng)后機械(xie)(xie)手(shou)取(qu)料(liao)放入(ru)到下道(dao)(dao)工(gong)(gong)(gong)序(xu),該設備是為了(le)實現工(gong)(gong)(gong)件(jian)的(de)翻(fan)(fan)面并且節省機械(xie)(xie)手(shou)作業動作。

1、性能穩定:這類設備是常用非標,海智具有大量的自動翻轉機構定制經驗,更加穩定成熟;

2、高效運行:伺服電機精確控制,滿足自動生產線的工件翻轉周期需要;

3、定位精準:全伺服電機控制,可以快速旋轉切換工件翻面生產,方便沖壓機械手生產;

4、安裝便捷:在出廠前海智機器人會完成安裝與調試并搭配機器人機械手進行翻轉設備聯機,運輸到現場固定即可使用;